With the introduction of the 90S+, Fujikura has also introduced the new Active Fusion Control (AFC) technology to further improve the dependability and consistent performance of core alignment fusion splicers. With each generation of fusion splicer development, Fujikura has continued to innovate and improve the state of the art in fusion splicing, and AFC in the 90S+ is the latest example.

With the introduction of the 90S+, Fujikura has also introduced the new Active Fusion Control (AFC) technology to further improve the dependability and consistent performance of core alignment fusion splicers. With each generation of fusion splicer development, Fujikura has continued to innovate and improve the state of the art in fusion splicing, and AFC in the 90S+ is the latest example.

Fujikura 90S+ Fusion Splicer

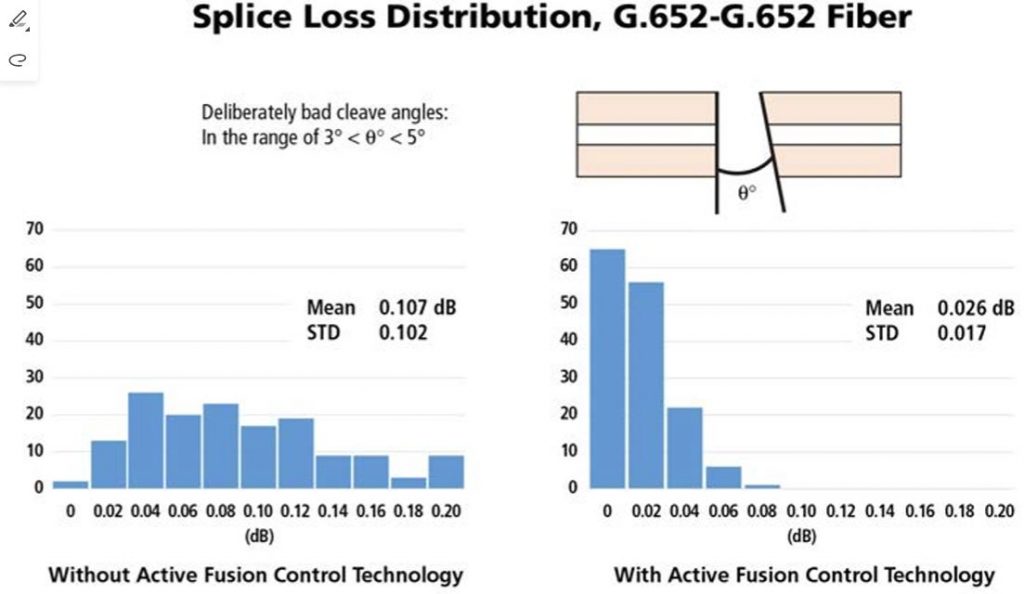

Splicers incorporating the Profile Alignment System (PAS) core alignment system have long been recognized as providing the most consistent and reliably low-loss splicing results. AFC further enhances the consistency of splicing performance by providing a sophisticated algorithm to alter the splicing parameters to mitigate against increased loss due to a poorly cleaved fiber end.

A less-than-ideal cleaved fiber end may result in core deformation at the splice point (micro-bending) and therefore higher loss. AFC uses the cleave quality monitoring system to consider when the cleave quality is such that the fusion parameters should be altered to avoid an elevated splice loss. To avoid the higher loss, more fusion heating time or power is required to create greater diffusion in the fiber core and lessen loss due to micro-bending. It should be noted however that a PAS core alignment splicer generally employs a relatively short, two-second arc time to ensure ultraprecise core alignment. If the arc time or power is too great, the cladding of the two fibers will self-center due to the surface tension of the molten glass during the fusion arc, and core alignment will not be maintained unless the cores are already perfectly in the center of the cladding. Therefore, sophistication is required in the proprietary analysis and algorithms of AFC to ensure it is used to the best advantage.

Splice loss results with poor cleave quality are shown with and without AFC. In this case, cleaves with angles in the range of 3° to 5º were deliberately created to illustrate the benefits of AFC.

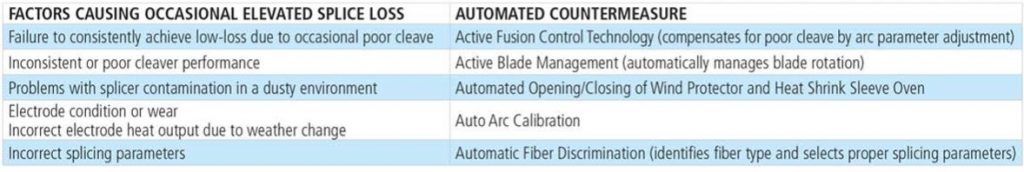

The introduction of AFC in the 90S+ is only the latest in a series of innovations and features that Fujikura has introduced to ensure consistent low-loss splicing results with PAS core alignment fusion splicers. The previous Fujikura introduction of Active Blade Management technology was another such innovation and is still unmatched by any other fusion splicer manufacturer. Active Blade Management utilizes Bluetooth® communications between the splicer and CT50 cleaver to monitor cleaving performance and automatically rotate the cleaver blade when cleaving consistency begins to degrade. With the combination of Active Blade Management technology (to prevent poor cleaving results as much as possible) and now AFC (to prevent high loss when a poor cleave is encountered), the 90S+ Splicer provides near-perfect immunity to cleaving-related issues.

The automated opening and closing of both the wind protector and the splice sleeve heat shrink oven is another example of Fujikura innovation. This provides an obvious boost to splicing productivity since it frees up the operator to concentrate on fiber preparation, wrapping completed splices into the splice tray, etc. However, the benefits go far beyond improvements in splicing operational time. In a dusty splicing environment, the automation of the wind protector and heat shrink oven can also be utilized to minimize the risk of dust getting into the splicer V-grooves (which might result in unstable core alignment) and to avoid contamination issues with the splice sleeve heat shrink process. These capabilities are also exclusive Fujikura fusion splicer features.

In a core alignment splicer, as noted above, a controlled arc time at the correct arc power is essential in order to ensure consistent and precise core alignment. Fujikura previously introduced Auto Arc Calibration to monitor the brightness of the glowing fibers during the arc, and thereby self-correct and fine-tune the arc power splice-by-splice, making small adjustments to the arc power as the electrode condition changes. While we still recommend a manual Arc Calibration at the start of daily splicing activities (especially if there has been a change in weather), the Auto Arc Calibration can also compensate for changes in atmospheric pressure which could otherwise result in a stronger or weaker arc intensity.

Fujikura also previously introduced Automatic Fiber Discrimination which can use image analysis to identify the fiber type being spliced in order to automatically ensure that the proper splice mode and arc parameters are used for that category of fiber. This is very helpful when the operator has some uncertainty in fiber type, and it works in conjunction with Auto Arc Calibration to ensure proper arc conditions and heating of the fibers during splicing. It should be noted that all of these innovations function automatically and are therefore not dependent on operator habits or skill, or operator attention to routine maintenance guidelines.

Summary of Fujikura innovations

Fusion splicers using the Profile Alignment System (PAS) can align single-mode fiber cores to a sub-micron accuracy, eliminating core-clad eccentricity as an issue. Purchasing a core alignment splicer is a significant investment, and the end user has a justifiable expectation of the best and most reliable low-loss fusion splicing. The Fujikura 90S+ is the only splicer to offer all of the automated features above to ensure consistent and repeatable low-loss splicing performance.